With the door (finally!) closed on 2022 and the worst of the COVID-19 pandemic seemingly only a memory, manufacturers are looking to the future with a new outlook and criticism. Supply chain problems, raw material delays, labour shortages, rising costs and increasing demand are forcing manufacturers to increase productivity and efficiency. 3D printers and photopolymerisers are equipment that are becoming increasingly important in any production plan. The most common cause of downtime is the use of incorrect or obsolete equipment. Here are some things to consider when you need to improve processes and increase productivity.

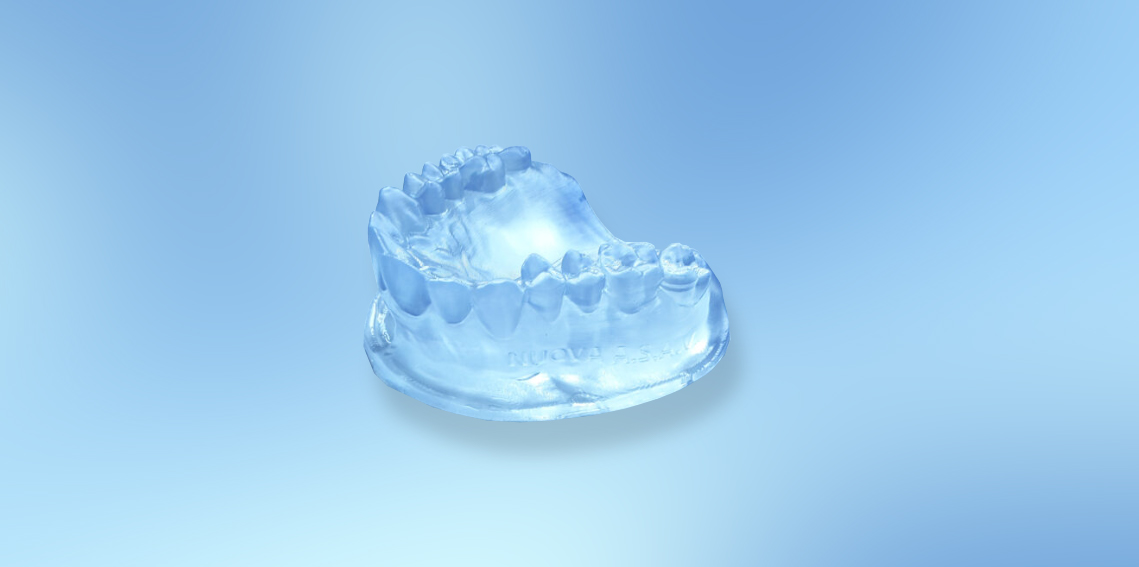

– Are you using correct light curing?

Actually, most resins can be used on a variety of different equipment that could produce the same end result, but the real cost of using the ‘wrong’ printer is time. In an ideal world, printing and curing equipment and procedures should be evaluated regularly as production requirements change and new products or raw materials are introduced. However, printing is rarely upgraded until it becomes a source of drastic losses due to low yields and recurring difficulties in achieving product quality.

Our advice is to carefully evaluate these variables.

– Sometimes more versatility is better.

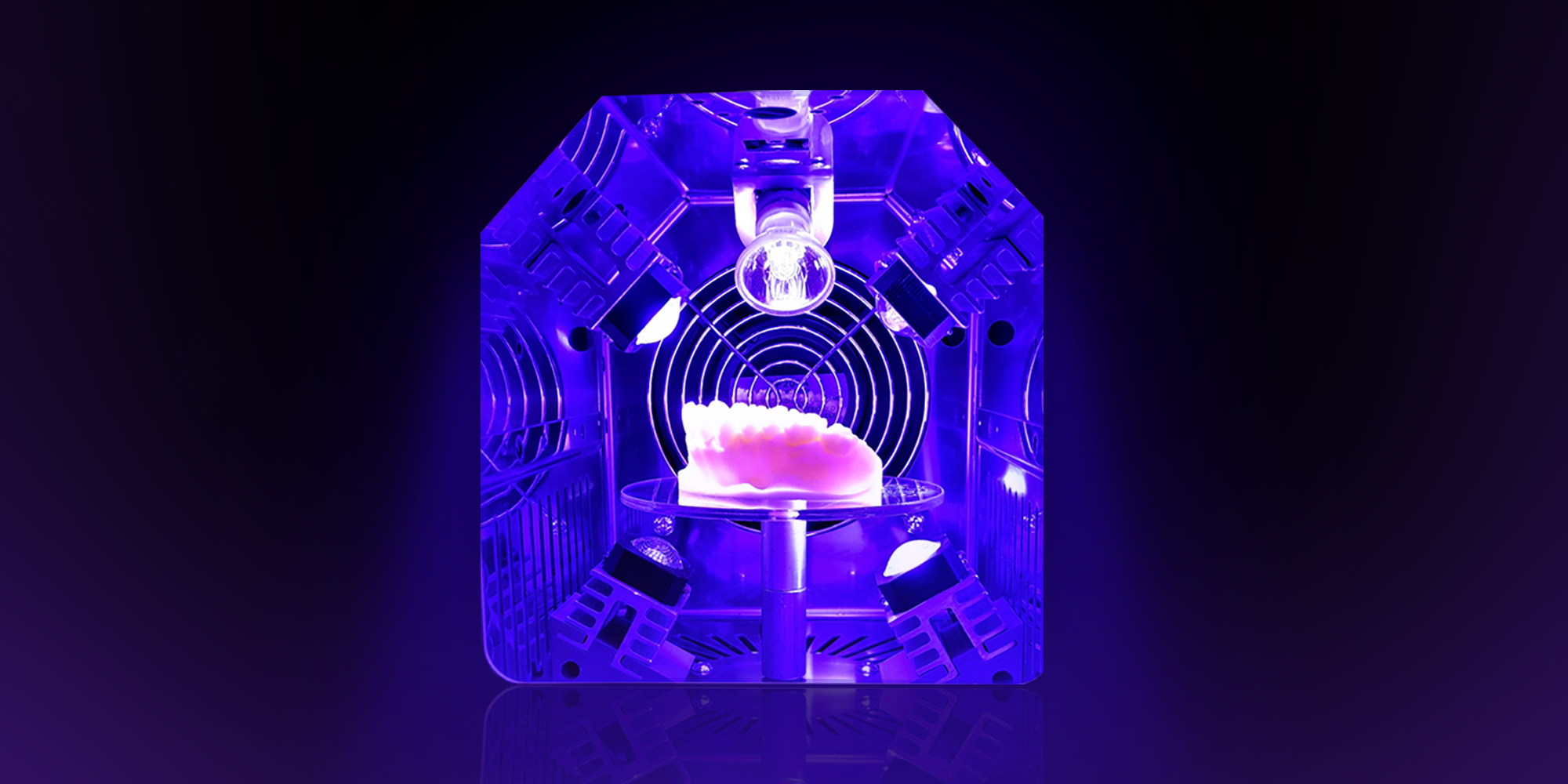

As customer demand increases and inflation continues to have an impact on raw material prices, increasing production can save time and money. Often, manufacturers respond to the need to increase production by adding more identical equipment to their existing machines. Although this strategy will improve production, it may not be the most cost-effective choice. With each square metre of space occupied by numerous small mixers, the associated labour and maintenance costs increase when using a multi-purpose unit that can cure both composites and 3D prints.

– Use technology to simplify.

The alternating light polymerisation method makes it possible to optimally select and manage the exposure of the model by varying the time and frequency of the light used.

The combination of light produced by the FMP PLUS can reduce cycle times by 50% or more. The model is hit by light beams from all directions inside the stainless steel chamber, making the polymer reaction homogeneous without creating surface tension. A controlled temperature of approximately 45 °C completes the correct polymer baking cycle.